Inorganic waterproof plugging material-plugging spirit

Category:

Products

Summary:

This product is a kind of powdery waterproof material with special plugging effect and processed by special cement and additives, which is used for moisture proof, anti-seepage and plugging projects. According to the setting time, the material is divided into two types: quick setting type and slow setting type.

Keywords:

Inorganic waterproof plugging material-plugging spirit

Features

●Moisture-proof, impermeable, and fast plugging;

●Construction can be carried on or away from the water, the construction is simple;

●No aging, good water resistance;

●Non-toxic, odorless, non-polluting, non-flammable, chemical resistant;

●High anti-seepage pressure, strong cohesive force, complete bonding in one time.

Construction process

Construction of leaking points:

●Basic treatment: first cut the leak point or leak seam into a V shape, and rinse out the debris;

●In the batching construction, mix the quick-setting type plugging spirit into powder: water = 1: 0.25-0.30, quickly mix it into a plugging material, knead the plugging material into a mass, and put it into a V-shaped groove after hardening to compact it. You can stop the leak instantly. The order of plugging should be to block small leaks first, then block large leaks.

●For the water seepage pit, quick-setting plugging dry powder can be directly put into the pit for compaction, smoothing and watering.

●For severe leaking joints, use the drainage method, make diversion holes at appropriate locations, and drain the leaked water together, plug the upper joint first, then plug the lower joint, and finally plug the drainage hole.

●For large-area leaks, first find out the leak point, first block it with quick-setting type plugging spirit, and then carry out waterproof treatment.

Construction of seepage base:

●Base surface treatment: After the base surface is cleaned and leveled, rinse it with water. Before construction, the base surface must be solid, clean, rough and fully moistened (no clear water). If the base surface has serious water leakage, quick-setting type can be used to stop the leakage Stop leaks, or make diversion holes at the bottom to reduce pressure, and then top-down construction.

●Ingredients: Use quick-setting type plugging agent to prepare the water-powder ratio of 0.3-0.5, mix evenly into a putty shape, and there should be no bubbles, hard lumps or raw powder in the powder.

●Construction: Dry the base surface with a dry cloth and quickly apply the first layer of material. If there is water leakage, do not use the tube first. After the coating is hardened, spray it (but no water), and then apply the second layer of material At the time of loading, it is necessary to scrape back and forth several times to make the coating dense. At the same time, pay attention to whether there is water seepage at the overlap. If there is water seepage, continue to apply the third layer until there is no water seepage. The material for each layer is about 1.2kg / m2, the total material is about 2.5-3.0kg / m ', and the total thickness of the coating is about 1.5- -2.0mm.

●Conservation: After the coating is hardened, moisturize and protect it immediately to ensure that the coating is wet to prevent powdering. The curing method can be sprayed with water, covered with wet objects, and sprayed with curing agent. Cured for 2-3 days. When the temperature is lower than 10C during construction, use quick-setting type leakers and stir with 40 ℃ warm water. Construction in the summer sun. It needs to be humidified and maintained. In winter, when the temperature is below -5 ℃, it needs to add 1-3% sodium nitrite by weight of the powder. Construction in the rain needs to prevent the rain from damaging the waterproof layer.

Scope of application

It can be used for various underground buildings or structures, cable channels, pools, toilet rooms, civil air defense tunnels, subways, tunnels, engineering moisture, impermeability, plugging, underground pipelines, running water, dams, equipment foundation emergency repair Grouting can also be used to paste tiles, mosaics, marbles and other block materials, which can make waterproofing and pasting completed in one go.

Type I (mangling type) is mainly used for waterproof and impermeable on damp and micro-permeable base.

Type II (quick-setting type) is mainly used for leak-proof or water-gushing substrates for waterproofing and leakage-increasing, and can be carried with water.

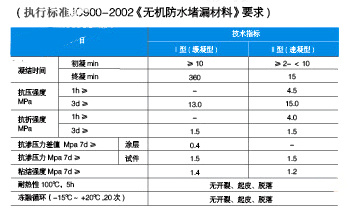

Technical performance index

Previous

Silicone exterior wall waterproofing agent

Online Consultation

More Products