Uncured rubber asphalt waterproof coating

Category:

Products

Summary:

● Uncured rubberized asphalt waterproof coating is a new type of waterproof material newly developed and produced by our company. The material is a one-component waterproof coating made of rubber powder, polymer, asphalt and other materials through special modifiers and additives. <br/> ● Uncured rubber asphalt waterproof coating will not solidify after long-term contact with air, insoluble in water, high bonding strength, can adapt to complex construction work surface; and can automatically find water leaking parts to repair damaged waterproof layer, permanently leak-proof; Contains solvents to meet national safety and environmental protection requirements. <br/> ● Non-cured rubber waterproof asphalt paint has outstanding creep performance, good waterproof performance, aging resistance, and can be applied by painting, spraying, grouting and other methods. It can be combined with the coiled material to form a composite waterproof layer; it can also be used alone as a waterproof layer, and the surface should be attached with an isolation layer. <br/>

Keywords:

Uncured rubber asphalt waterproof coating

Application range

●The product is suitable for bases with large undulations and high stress, and parts with predictable and frequent deformation; especially suitable for projects where open flame construction, mechanical construction and cold adhesive construction cannot be used;

●It is suitable for waterproof works such as concrete, color steel and other roofing, underground, pool and tunnel.

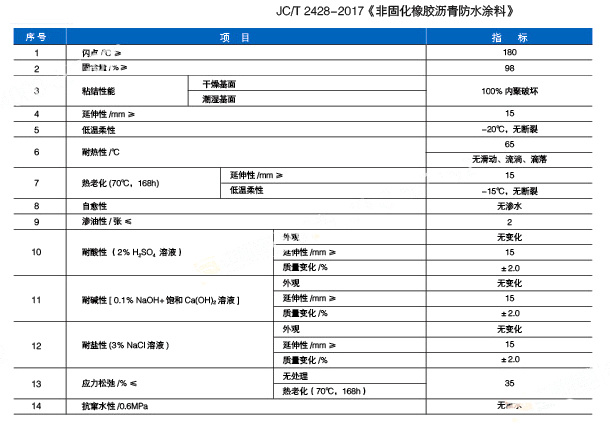

Executive Standard

Performance characteristics

●Excellent grassroots adaptability:

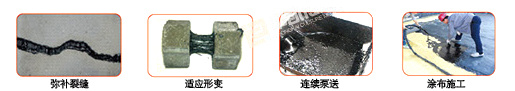

The material can adapt well to the structural deformation. When the base layer is cracked and the waterproof layer is stretched, the non-cured rubber asphalt waterproof layer absorbs the stress and closes the micro cracks in the base layer to ensure the long-term integrity of the entire waterproof system.

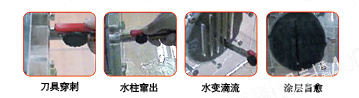

●Outstanding self-healing ability:

When the waterproof layer is punctured by external force, the damage point will not expand, and the bottom of the waterproof layer will not have water channeling, and the creep performance of the material will heal slightly leakage problem, which improves the reliability of the waterproof layer. Reduced engineering maintenance costs.

●Excellent aging resistance, low temperature flexibility, corrosion resistance

●Strong cohesive force: it can be drilled with different bases, even on a wet base, it also has good cohesive force.

●Good constructability: solid content above 99%, feeding, pumping, continuous construction, can be applied to the specified thickness at a time, the construction speed can reach 115m2 / h. Safety and environmental protection: non-toxic, solvent-free, no open flame during construction, safe and environmentally friendly.

Construction points

●Clean up the grassroots

If the surface of the base layer is obviously uneven, it should be smoothed with cement mortar first; the pipelines, embedded parts and equipment foundations that pass through the waterproof layer should be buried and installed before the waterproof layer is constructed. The gap between the pipeline and the structure should be blocked with fine stone concrete or polymer waterproof mortar. Use a broom or hair dryer to clean up the basic mortar and construction waste. The base layer accepted shall be flat and solid, the drainage slope shall meet the design requirements, the base layer may be wet, but there shall be no clear water.

●Detailed additional layer construction

The rainwater inlet of the roof, the root of the pipe exiting the roof, the yin and yang corners of the parapet, the gutter, etc. are first scraped and coated with 1mm non-cured rubber asphalt waterproof coating for enhanced treatment.

●Paint construction

The coating can be applied by scraping or spraying method, and the squeeze pump is turned on to extrude the non-cured rubber asphalt waterproof coating to the base layer.

●Paving rolls

Immediately, the roll material is laid on the surface of the completed waterproof coating, and it is required to be laid straight, flat and without wrinkles. The coiling width of the coil is 100mm, and the lapped part is in the form of cold adhesion, and the non-cured rubber asphalt waterproof coating is scraped or sprayed within the lap width of the coil, without the need for surface drying time, and the lapped part can be directly constructed And rolled.

●Water storage test

After the waterproof layer is completed, carry out the water storage test according to the regulations. It is qualified if there is no leakage for 24h.

●Protective layer construction

After the quality acceptance of the roof waterproof layer is qualified, the protective layer construction can be carried out. According to the design requirements, make the corresponding concrete, block material or cement mortar protective layer.

Ingredient dosage

According to the amount of construction, stir and use evenly. The reference dosage is: The dosage of 1mm thick coating is about 2.5-3KG / m2

Previous

Inorganic waterproof plugging material-plugging spirit

Online Consultation

More Products