Spraying quick-setting rubber asphalt waterproof coating

Category:

Products

Summary:

Two-component spraying quick-setting rubber asphalt waterproof coating, component A is the main agent. It is composed of anionic synthetic rubber emulsion, emulsified asphalt microemulsion made by special process and various chemical additives. It is a continuous phase. Asphalt is a core-shell structure composed of a dispersed phase. Its solid content is high and its single viscosity is low. It is suitable for spraying construction. Component B is a coagulant, which is formulated into an aqueous solution of corresponding concentration from electrolytes such as metal salts.

Keywords:

Spraying quick-setting rubber asphalt waterproof coating

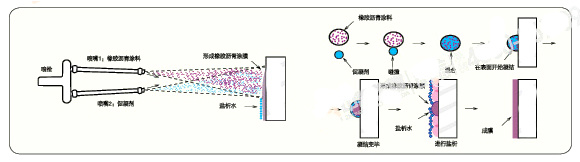

Film formation mechanism

The components A and B of the quick-setting rubber asphalt waterproof coating are sprayed through the two nozzles in the airless spraying equipment, fan-shaped high-speed spraying, atomization, cross collision, and spraying to the base surface. Under the action of the agent, the charge stability of the polymer emulsion and emulsified asphalt is destroyed, causing it to break emulsion quickly, salt out water, and coagulate into a polymer film instantly.

Construction process

The construction spraying of the product is completed by special spraying equipment. At normal temperature, the two groups of the product are sprayed and atomized by the two nozzles through the pipeline, and the high-speed mixing. The material immediately condenses into a film after spraying on the base surface, and the spraying efficiency is high , To save labor, shorten the construction period and reduce construction costs.

●Product construction process flow chart

Machine tool preparation, material preparation → grassroots treatment → detail construction → spraying construction → quality inspection → quality acceptance → finished product maintenance → protective layer construction.

●Basic treatment

①The base layer should be firm and flat, and there should be no looseness, sand, or peeling; ②The base layer should be clean, free of floating dust, oil ulcers, and debris; ③The base layer can be wet, but there must be no clear water.

●Detail enhancement

All details must be strengthened before spraying. Mainly the yin and yang angles, the roots of the deformed joint tool column, etc., which are applied by the brushing method and applied in multiple passes. The carcass reinforcing material should be sandwiched between the coatings, and be firmly adhered, without hollowing or warping.

●Spray requirements when there is reinforcement material

① Carcass reinforcement materials should be paved after the bottom coating is cured:;

② The thickness of the bottom coating film should not be less than 0.5mm;

③ The long-side lap width of the reinforced material shall not be less than 100mm, and the short-side lap width shall not be less than 150mm. Use special sealant to bond the carcass lap seam.

Performance characteristics

●Excellent tensile resistance

The product has an elongation at break of more than 1800%, a tensile strength of up to 2MPa, and a retention rate of more than 95%. It can adapt to the deformation of the base layer and can solve the problem of waterproof leakage caused by stress deformation, expansion cracking, etc. of waterproof materials.

●Good bonding strength

The product can be sprayed on different base layers, the peel strength with concrete is not less than 4.0N / mm, and with wood and metal plates is not less than 2.0N / mm, can be firmly attached to the surface of various materials such as concrete, wood and metal , Do not fall off.

●Excellent self-healing

This product has the characteristics of liquid rubber. It has good self-healing ability to puncture the knife and sharp objects, and has excellent resistance to knocking and water tightness of the nail rod.

●Excellent puncture resistance

After spraying into a film, the product can form a high-strength waterproof film, with excellent puncture resistance, crack resistance, and tear resistance.

●Has chemical resistance

The product has excellent resistance to acid, alkali and salt. Placed in acid, alkali and salt environment for 168h, the tensile strength retention rate reaches more than 95%, and the elongation at break is higher than 1000%.

●Excellent high and low temperature resistance

The product has both good low-temperature bendability and excellent high-temperature resistance. According to the needs of different regional projects, the low-temperature flexibility can be adjusted between -15 ℃ and -40 ℃ to meet the needs of the project. Above 180 ℃, it can be applied to the waterproof engineering of roads, bridges and high hot areas.

●Excellent water resistance

The product has good waterproof performance, can withstand high water pressure after spraying into a film, and the maximum static pressure resistance is 3MPa 1h without water penetration.

●Can be constructed on wet base

The product can be applied on a damp, clear water base surface. After spraying, it can be instantaneously formed, and the next process can be carried out, which shortens the construction cycle and reduces the construction cost.

●Excellent anti-aging properties

This product contains anti-ultraviolet aging agent and a high proportion of functional polymers, which gives the product excellent anti-aging properties. Under the conditions of artificial accelerated weathering treatment and ultraviolet treatment for 250h, the tensile strength retention rate reaches more than 95%.

●Has outstanding environmental protection and safety

In the production, construction and use of this product, no organic solvents are used, non-toxic, odorless, no waste, no exhaust emissions, no pollution; in the construction project, no heating is required, normal temperature construction, no open flame, to ensure the safety of construction And reliability.

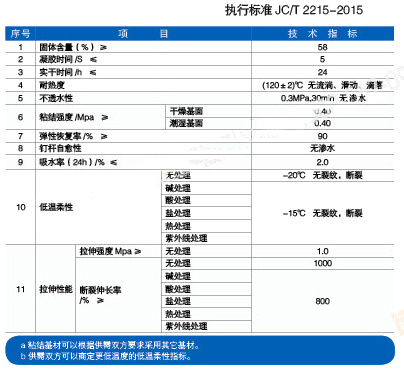

Product performance

Application range

This product can be widely used in building foundation, kitchen and bathroom and roof waterproofing, various types of storage tanks, subways, tunnels and culverts, water conservancy facilities, road and bridge waterproofing and lining; and color steel tiles, roofs, etc. Protection of many steel structures.

Previous

(For high-speed rail) High-strength polyurethane waterproof coating

Online Consultation

More Products