(For high-speed rail) High-strength polyurethane waterproof coating

Category:

Products

Summary:

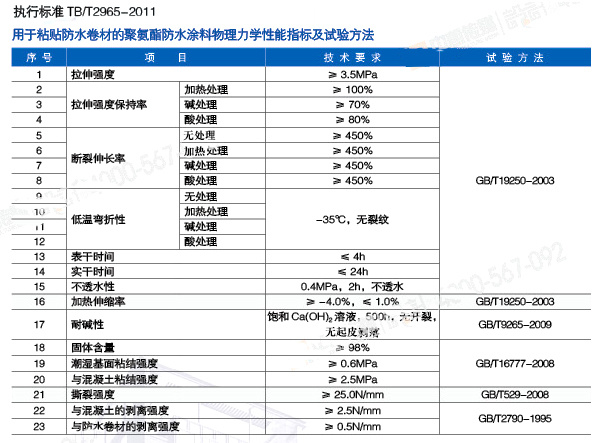

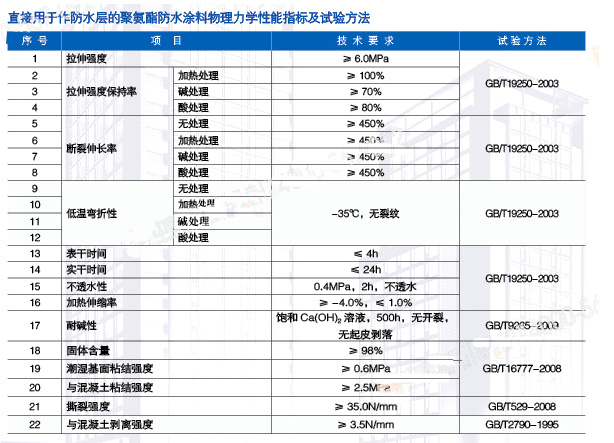

(Special for high-speed rail) High-strength polyurethane waterproof coating belongs to two-component chemical reaction type waterproofing material, in which component A is an isocyanate-terminated prepolymer obtained by polycondensation of polyether and isoalanate, and component B A colored liquid composed of reinforcing agent, plasticizer, rent-enhancing agent and accelerator. When used, mix the two components of A and B in proportion, and paint on the waterproof base layer, often cross-linking and curing at warm temperature to form high strength Extended rubbery elastic coating.

Keywords:

(For high-speed rail) High-strength polyurethane waterproof coating

Features

●This product is a two-component chemical reaction curing type waterproof material, which is an environmentally friendly product. The product strength can reach 6.0Mpa or more, the elongation can reach 450% or more, and the low temperature reaches -35 ℃. The complete elastic waterproof layer, especially with high strength and extensibility, has strong adaptability to cracking or stretching of the base layer.

●The product is easy to construct. Only the A and B components need to be mixed in proportion during the construction, and it can be applied on the waterproof base layer. It is a cold construction waterproof coating.

●Convenient maintenance, only need to repair the damaged parts to achieve the original waterproof effect, save time, effort and low cost.

●The color can be adjusted to meet the needs of different colors.

Adaptation

Suitable for waterproof construction of high-speed railways, viaducts, highways, etc. Waterproofing for civil and industrial roofing and underground engineering, municipal administration, bridges, subways, dams and other projects is more suitable for waterproof construction with complex shapes and vertical and horizontal parts of pipes.

Construction process

●The base layer needs to be firm, flat, free of debris, and dry. The female and male corners should be rounded. The female corner diameter is greater than 50mm and the male corner diameter is greater than 10mm.

●Ingredients and dosage: Mix the two components of A and B in proportion according to the construction dosage, stir and use evenly. The reference dosage is: The dosage of 1mm thick coating is about 1.3 ~ 1.5kg / m2. Large area waterproof construction: evenly mix the mixed paint with rubber or plastic scraper, the thickness is required to be the same, generally 1.5mm-2.0mm, should be divided into 3-4 brushes, the second brush should be cured in the previous brush After the film is formed and painted in a vertical direction, an additional layer of carcass reinforcement should be placed on the floor of the underground project.

●Coating film thickness: subway project should not be less than 2.0mm, underground project should not be less than 1.5mm, toilet room should not be less than 1.2mm, when the carcass reinforcement is added in the coating room, the coating under the tire The thickness above 1.0mm is not less than 0.5mn.

●Close and edge treatment: add coating to close.

●Protection layer: The surface of the coating waterproof layer should be isolated and protected according to the design requirements.

Previous

Modified asphalt waterproof coating for road and bridge

Online Consultation

More Products