Self-adhesive polymer modified asphalt waterproof membrane

Category:

Products

Summary:

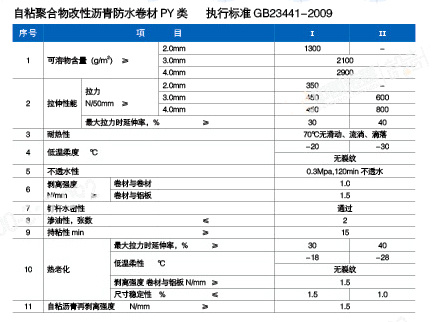

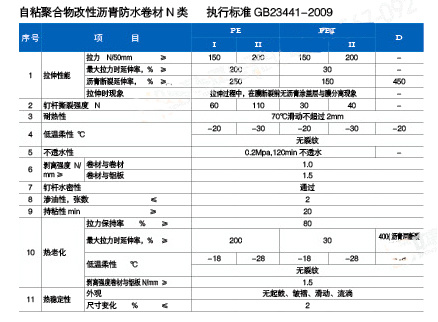

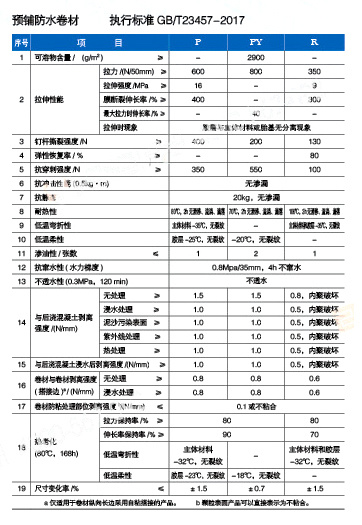

Self-adhesive polymer modified bitumen waterproof membrane (hereinafter referred to as N type) is based on SBS and other synthetic rubber, high-quality road asphalt and tackifier, with polyester film (PET), polyethylene film (PE), aluminum foil Xiao-coated silicon isolation membrane is the upper surface material, and the lower surface is covered with silicon-coated isolation membrane as the anti-sticking layer and is a self-adhesive polymer modified asphalt tireless waterproof membrane. <br/> Self-adhesive polymer modified asphalt polyester tire waterproof membrane (hereinafter referred to as PY type) is based on filament polyester felt as the tire base, using tackified polymer modified asphalt as the dipping coating material, and the upper surface is covered with polyethylene film , Fine. Shale, aluminum foil or isolation film is the isolation layer, and the lower surface is coated with a silicon isolation film as an anti-adhesive layer. It is a self-adhesive polymer modified asphalt polyester tire waterproof membrane. Wide-width self-adhesive pre-laid polyester tire waterproof membrane (hereinafter referred to as pre-laid PY type) is based on asphalt-based polyester tire waterproof membrane as the main material (adding functional additives), coated with a self-adhesive layer on both sides, and attached Self-adhesive waterproof membrane made of peeled silicon-coated membrane as a separator. <br/> Wide-width self-adhesive polymer pre-laid waterproof membrane (hereinafter referred to as pre-laid P type) is based on ethylene-vinyl acetate (EVA) and high-density polyethylene (HDPE) homogeneous sheets as the main material, and the surface is covered with a "self-adhesive layer" ", Then covered with polymer self-adhesive waterproof membrane made of silicon-coated membrane. According to engineering needs, geotextile can be compounded on the polymer layer to strengthen the strength of the coiled material. <br/> Wide-width wet-laid polyester tire waterproofing membrane is based on asphalt-based polyester tire waterproofing membrane as the main material (adding functional additives), with a self-adhesive layer coated on one or both sides, with a peelable silicon-coated film as Wet laid waterproof membrane made of insulation material.

Keywords:

Self-adhesive polymer modified asphalt waterproof membrane

Features

●Cold construction: no open flame, no adhesive, energy saving, environmental protection, low carbon, economy; excellent low temperature performance;

●Excellent adhesion performance: excellent adhesion performance with the base layer, avoiding the occurrence of water channeling. With self-healing function, the seam itself can be bonded with the same life as the coil;

●High tensile strength, high elongation, puncture resistance and corrosion resistance;

●Wide-width coil material has less construction loss and more convenient construction.

Scope of application

Waterproofing of non-exposed roofs and underground works; waterproofing of municipal works such as drains and swimming pools; waterproofing of subway works such as open cuts; especially suitable for waterproofing works where open flames cannot be used; excellent low temperature performance is more suitable for use in cold areas.

System type and scope of application

●Self-adhesive waterproof system: a system that uses wide self-adhesive polymer-modified asphalt waterproof membrane to perform full adhesion. It is suitable for roofs and underground with stable structure and waterproof parts with full bonding required by technical specifications. Applicable materials include wide self-adhesive polymer modified asphalt waterproof membrane, self-adhesive polymer modified asphalt polyester tire waterproof membrane.

●Pre-paved anti-stick waterproof system: that is, pre-paved coiled materials before pouring concrete and side walls of structural panels. Applicable materials are pre-laid anti-adhesive polymer modified asphalt waterproof membrane, wide-width self-adhesive EVA / HDPE polymer waterproof membrane

●Waterproofing system for wet shop: The materials used are wide wet-laying waterproof membrane.

Wet shop waterproof system

●Construction process

Clean the base surface → wet the base layer (if the base layer is wet, this process is not required) → positioning, bullets → mixing and spreading the cement slurry → laying the coiled material → lifting, venting, airing → lapped edge sealing → rolling Head, seal → inspection and acceptance

●Basic requirements: The surface of the base should be firm, clean, moist and free of water.

●Construction of additional layers of nodes: Add additional layers to the nodes according to relevant specifications or design requirements.

●Laying large-surface waterproof membrane: spread cement mortar-general thickness 2-3mm (depending on the flatness of the base layer), remove the insulation film on the lower surface of the waterproof membrane and flatten the membrane in water

On mud mortar. The coil and the adjacent coil are parallel butted.

●Pulping: beat the coil with a wooden trowel or rubber plate. The upper surface excludes the air below the coil, so that the coil and the mortar closely fit.

●Conservation: Curing for 48 hours after the completion of coiling (the specific time is determined according to the ambient temperature during construction).

●Coiling material lap seam treatment: After cleaning up the lap joints, uncover the upper side of the web lap joint isolation film and press the self-adhesive sealing strip to cover the butt joints.

Self-adhesive waterproof system

●Applicable waterproof membrane series: self-adhesive polymer modified asphalt polyester tire waterproof membrane, self-adhesive polymer modified asphalt waterproof membrane, self-adhesive EVA / HDPE polymer waterproof membrane

●Construction process flow:

Construction preparation → Base layer treatment → Brushing supporting base layer treatment agent → Construction of additional layers of detail nodes → Bouncing datum line → Large surface self-adhesive coiled material paving → Exhaust compaction → Lap edge compaction and sealing → Facade coil material collection Head fixing and sealing → inspection and acceptance → protective layer construction

●Construction preparation: including main materials, auxiliary materials, construction base, on-site conditions, technical solutions, etc.

●Base layer treatment: The base layer should meet the requirements of the specification, and should be flat, clean and dry; the yin and yang angles at the junction of the flat and vertical surfaces should be made into arcs.

●Brush the base layer treatment agent After the base layer treatment meets the requirements, the base layer surface is painted (or sprayed) to match the base layer treatment agent. The coating (or spraying) of the base treatment agent should be even and consistent, and should not be exposed. The surface should be dried before the roll material is applied.

●Construction of additional layers of nodes: Add additional layers to the nodes according to relevant specifications or design requirements. The additional layer of general parts is full of stickiness, and the parts with stress concentration should be laid empty according to the requirements of relevant regulations.

●Laying large waterproof membrane:

●Horizontal spreading: firstly pop up a base line on the base layer, then spread from low to high, unwind the roll while peeling off the release paper, spread along the base line, and the width of the roll is ≥100mm. Immediately after paving, the roll should be compacted with a pressure roller.

●Vertical surface paving: The vertical surface is paved from low to high, and the isolation film is uncovered while unfolding. The width of the overlapping edge is the same as above; after paving, use the pressure roller to compact it.

●Side wall waterproof layer construction: first position the coiled material on the base layer of the underground continuous wall according to the elastic reference line, the self-adhesive isolation membrane of the coiled material faces the side wall structure, and use special concrete steel nails to fix the coiled material in the underground continuous On the base layer of the wall; peel off the isolation film on the edge of the joint and make a long-side lap. After tapping, immediately press and roll to seal firmly. After the short side overlaps, use the matching sealing paste to seal. At the end of the vertical wall project, it can be fixed with a closing bead and sealed with sealing paste. After the coil is laid, the isolation film on the coil waterproof layer can be torn off.

●Coil end: It should be sealed with sealant at the end, and then fixed with metal bead.

●Protective layer construction: according to design requirements.

Pre-paved anti-stain waterproof system

●Used waterproof membrane series: wide pre-laid polyester tire waterproof membrane

●Construction process flow: base layer cleaning → node node strengthening treatment → laying of waterproof coiled material → tapping coiled material → node sealing → removing the membrane on the surface of the coiled material and sprinkling cement powder → quality acceptance

●Construction preparation: including main materials, auxiliary materials, construction base, on-site conditions, technical solutions, etc.

●Basic requirements: The surface of the base should be firm, dense and flat without debris. The base can be wet but no clear water. The yin and yang angles at the junction of the flat elevations should be made into uniform and uniform arcs as required.

●Construction of additional layers of nodes: Add additional layers to the nodes according to relevant specifications or design requirements. The additional layer of general parts is full of sticky, and the parts with stress concentration should be laid empty according to the requirements of relevant regulations.

●Laying large waterproof membrane

●Plane construction: On the surface of the qualified base, keep the size of the lap seam according to the width of the coil, pop up the reference line, and then lay the coil on the base, and correct the position of the coil. The polyethylene film of the coil material faces the base layer, and the self-adhesive layer isolation film faces the construction personnel. The coil material is rolled while laying the coil material to eliminate air from the lower surface of the coil material. The lap joints are connected by self-adhesive method.

●Facade construction: first position the coiled material on the base layer of the facade in accordance with the elastic reference line to face the facade structure. Use special concrete nails to fix the coiled material to the base of the facade. Uncover the isolation film of the overlapped edge, and perform the long edge overlap, the overlap width is not less than 100mm. Make sure that all nail heads are covered by adjacent coils. Immediately after tapping, roll with a pressure roller to seal. The short edge overlap width is 100mm. After the overlapping of the long and short sides is completed, the sealing paste is used for sealing. The closing part of the facade can be fixed with a closing bar and sealed with sealing paste. After the construction of all coils, the membrane waterproof layer. The upper surface isolation film can be torn off.

When the base is damp or the temperature of the construction environment is low, appropriate heating treatment can be used when the coils are overlapped.

Previous

Elastomer / plastic body APP modified asphalt waterproof membrane

Online Consultation

More Products