Elastomer / plastic body APP modified asphalt waterproof membrane

Category:

Products

Summary:

APP Plastomer-modified asphalt waterproof coiled material is made of APP (random polypropylene) or APAO, APO (polyolefin polymer) modified asphalt as dipping coating material, and high-quality polyester felt and glass fiber felt as the tire base Fine sand, mineral granules (sheets), PE film are surface materials, plastic body modified asphalt waterproof coiled material refined by advanced technology.

Keywords:

Elastomer / plastic body APP modified asphalt waterproof membrane

Features

Polyester tire APP modified asphalt waterproof membrane

●Strong impermeability

●High tensile strength, high elongation, and strong adaptability to shrinkage and cracking of the base

●Good high temperature resistance, corrosion resistance, mildew resistance, good weather resistance, puncture resistance, puncture resistance, tear resistance

●Convenient construction, hot melt construction can be operated in all seasons, and the joint is reliable, especially suitable for building waterproofing with large structural deformation and high temperature environment.

Glass fiber tire APP modified asphalt waterproof membrane

●High tensile strength and good size rating

●Good high temperature resistance

●Damage resistance, corrosion resistance, mildew resistance, good weather resistance

●Good construction performance and reliable joints

●Convenient construction, hot melt construction can be operated in all seasons, and the joints are reliable, especially suitable for building waterproofing in higher temperature environments.

Adaptation

Waterproof and moisture proof for roofing, walls, basements, toilets, etc. of key waterproofing projects and industrial and civil buildings; bridges, roads,Waterproofing of parking lots, swimming pools, tunnels, cisterns and other buildings: especially suitable for buildings with frequent structural deformation and cold areas, Protection of pipeline anti-corrosion layer and guarantee, moisture-proof.

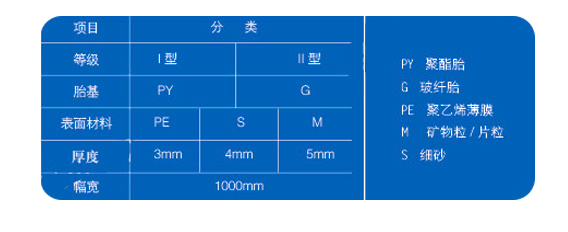

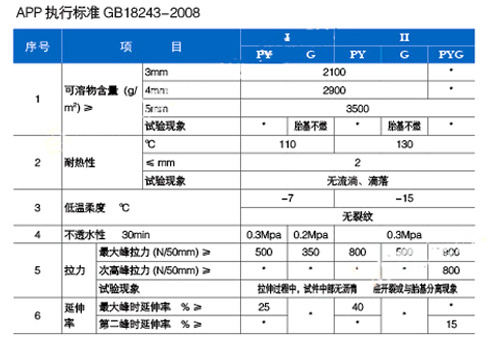

Variety specifications

Product index

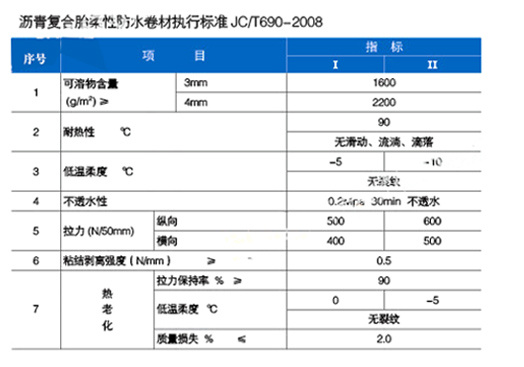

Elements of waterproof construction

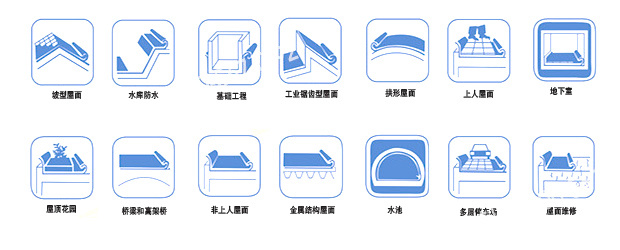

Waterproof point map

Construction application

The key waterproofing membrane can be constructed by hot melt method or cold bonding method alone, or by combining cold and hot method, that is, cold bonding method for large area.

The joints are constructed by hot melting.

Coiled material

●Before the construction, the base layer of the acceptance inspection should be cleaned up, and the dust at the corners should be blown away.

●Apply the base treatment agent to the baby uniformly, do not apply it repeatedly.

●After the base layer treatment agent is dried, the roof waterproof project and the underground waterproof project need to be added as an additional layer according to the design requirements.

Place additional layers on the site.

●Determine the laying order and direction of the coiled material and stretch the line at the base layer, then lay the coiled material and paste different parts of the coiled material

Construction should be in accordance with the following requirements.

●Roof: Paste or strip paste on the roll material and the base; 800mm around the roof should be fully pasted; sloping roof paste wine product

100% full paste between more than 70% coils and coils;

●Basement bottom plate: Coil and base can be fully glued, point glued, strip glued or empty paved, but the material must be fully glued between the coils;

●The basement wall: all the materials should be pasted between the coil and the base and between the coil and the coil;

●Additional layer:-General parts are fully pasted, and empty joints are allowed at the deformation joints.

●The order of paving is high-span first, then low-span; same height, first far and then near; same-plane, starting from low place.

●Roofing direction of roof:

●Slope <3% parallel to the roof direction

●Slope 3% ~ 15% parallel or perpendicular to the roof ridge direction

●When the slope is greater than 15% or is subject to vibration, it should be perpendicular to the roof ridge

●The joints parallel to the roof ridge are in the direction of water flow, and when they are perpendicular to the roof ridge, the joints should be paved along the prevailing wind direction.

Coil construction method

●Long edge lap: The width of the longitudinal lap of the coil should be ≥80mm, it must be carefully operated, and the adhesive should be evenly applied, not

It must be missed. Excess adhesive should be squeezed out of the edge of the cold-adhesive roll. The hot-melt method should form an asphalt strip on the side.

●Short edge overlap: both ends of the coil must be bonded. The tapping width should be ≥100mm, when using polyester tire coiled material

When empty paving, the two ends must be fully bonded over 500mm: cold bonding method: there should be adhesive extrusion at the seam. Hot melt method:

Asphalt strips should be extruded at the seams.

●When laying two adjacent rolls of the same layer, the horizontal overlapping edges should be staggered by more than 150mm, and the upper and lower layers of rolls are prohibited

Lay perpendicular to each other. .

●Remove the shale layer when the short side of the coiled material with shale sheet is overlapped. The method is to scrape the shale part with a trowel after heating with flame.

Butt joints can also be used. The method is to place a 300mm coil strip under the seam, butt the coil horizontally, and use it at the seam.

Sealing material handling.

●After the roll material is laid, the overlapping parts, ends and ends of the roll material must be sealed. Should be packed

Seal the material, sealant or cold adhesive, and then smooth it to form a clear asphalt strip.

Schematic diagram of waterproof membrane construction

Previous

Elastomer / plastic body SBS modified asphalt waterproof membrane

Online Consultation

More Products