EPDM waterproof membrane

Category:

Products

Summary:

EPDM waterproof membrane adopts professional level cold feed extrusion continuous vulcanization process equipment, selects high-quality EPDM rubber and original materials, adds carbon black reinforcing agent, nano modifier, plasticizing Agents, vulcanization accelerators and other processing aids, through the process of dense mixing, refining, filtration, extrusion molding, continuous vulcanization, inspection, etc., processed into highly elastic synthetic polymer waterproof membrane.

Keywords:

EPDM waterproof membrane

Features

●Excellent anti-aging performance, service life up to 50 years.

●Extremely high elongation, relatively high tensile strength, small change in heat treatment size.

●Good plant root penetration resistance, can be used as a waterproof roof for planting roofs.

●Good flexibility at low temperature, good performance in adapting to environmental temperature changes.

●Special modified molecular structure effectively solves the problems of the existing overlap of EPDM adhesives at home and abroad.

●Convenient construction, firm and reliable lap joint, no environmental pollution.

●Resistant to chemical corrosion, can be used in special occasions.

●Convenient maintenance and low cost.

●Easy to handle details.

●Good perforation resistance.

Adaptation

Suitable for waterproofing of various roofs, basements, tunnels, etc. Civil and industrial roofing and underground engineering, water storage tanks, municipalities, bridges, subways, tunnels, dams and other projects, especially for durability and corrosion resistance High and easily deformable key waterproof works.

Construction requirements

●Basic treatment: The waterproof base should be firm, smooth, clean and dry (moisture content ≤9%) without dust or oil. The corners of the roof should be made into arcs or triangles with a radius of ≥20mm. The drainage slope, split joints, vents, etc. of the roof should be treated according to the design requirements.

●Construction method: Full paving method, empty paving method, upside down method and mechanical fixing method can be adopted according to engineering requirements.

●The bonding of the roll material and the base layer: the base layer and the roll material to be bonded are evenly coated with the base layer glue, and then dried (slightly sticky but not brushed) for bonding.

●The bonding of the overlapped parts (the lap width shall be in accordance with the specifications); the roll material of the overlapped parts shall be cleaned with cotton yarn dipped in the supporting thinner before being coated with glue. After applying lap glue to the surface (slightly sticky but not brushed, lap glue needs to be coated with more glue), stick the lapped part firmly, flatten it, and smash it tightly with a rubber hammer.

●Add additional layers according to the design requirements of the node parts. The additional layers can be treated with coiled material or polyurethane coating (if necessary, tire base cloth can be added).

●If you need to make a protective layer, according to the situation of the protective layer-generally need to be an isolation layer, the coiled material can be coated with protective paint, which can play the role of thermal insulation and extend the service life.

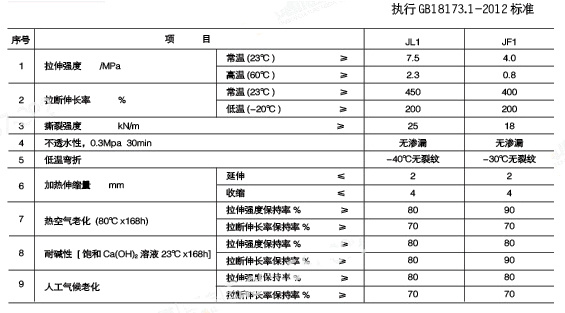

Technical performance index

Previous

Thermoplastic polyolefin (TPO) waterproof membrane

Online Consultation

More Products