Pre-laid polymer self-adhesive film (non-asphalt-based) waterproof membrane

Category:

Products

Summary:

Polymer self-adhesive film (non-asphalt-based) waterproof membrane is a waterproof material specially developed for building waterproof pre-paved parts. The membrane consists of polymer sheet, polymer self-adhesive film and anti-adhesive layer Non-asphalt-based polymer pre-paved waterproof membrane developed for fusion with concrete structure. <br/> Under the action of pressure, the polymer self-adhesive film and the uninitialized cement slurry will creep through the anti-sticking layer to form an effective interpenetrating bond and a huge intermolecular force. After the concrete is cured, the gap between the polymer pre-paved waterproof membrane and the main body of the structure is permanently sealed to the utmost extent, completely eliminating the channel for water channeling.

Keywords:

Pre-laid polymer self-adhesive film (non-asphalt-based) waterproof membrane

Features

●Pre-bonded

It can be adhered with the concrete poured in the future, and it is still inseparable under long-term foaming, which solves the waterproof problem of pre-paving (outer anti-inner paste).

●Reliable bonding, easy to overhaul

The waterproof membrane is tightly bonded to the post-cast concrete. If any local damage occurs to the coil, the water will be limited to a small range without channeling. Even if individual leakage occurs, the leakage point will be the same as the damage point and it is easy to repair.

●Low base requirement, saving construction period

It can be applied on wet or even leveling bases, without primer, with high degree of freedom in construction and not affected by weather. During the rainy season, the advantages are more prominent and it is the most powerful "weapon" to guarantee the construction period

●Safety and environmental protection

Solvent and fuel are omitted during the construction process, environmental pollution and hidden fire hazards are avoided, and resources are saved.

●Excellent physical properties

It has excellent tensile, elongation, root puncture resistance, weather resistance, strong ability to adapt to the deformation of the base layer and so on.

●Optimal cost performance

It can be combined with post-cast concrete structural layer to build a strong waterproof system with exceptional "skin" type, high reliability, and can also save the traditional cement mortar leveling layer and fine stone concrete protective layer, saving related costs and low system cost .

Application field

The basement, subway, tunnel, pool, inclined roof and flat roof are waterproof, especially suitable for waterproof projects with special environments and high waterproof requirements; planting green roofs; underground gas, biogas and other gas leakage prevention.

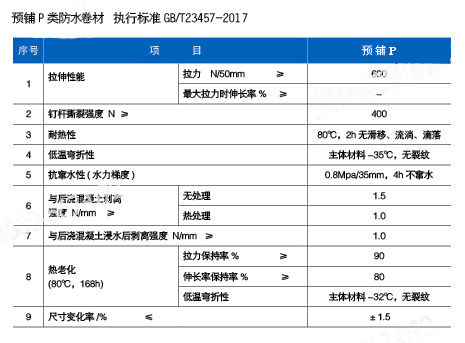

Performance

Construction process

●Plastic coil construction process

Clean up the base layer → base layer elastic wire → lay waterproof coiled material → coiled material joint → detail node processing → self-check, repair, acceptance → binding steel bar → pouring concrete

●Facade coil construction process

Leveling of the base layer of the envelope (or installing wooden boards) → detection, cleaning of the base layer of the facade → coil positioning elastic wire → laying of waterproof coiled material and mechanical fixing → coiling of the coil → detail node processing → self-inspection, repair, acceptance → Bundling steel bars → pouring concrete

Construction method

●Basic treatment: use shovel, broom and other tools to remove the construction waste on the basic level. If there is clear water, it needs to be removed.

●The air-laid polymer self-adhesive waterproof membrane: it is better to stretch the line on the cushion first to determine the reference position of the membrane. With the self-adhesive side of the coil facing up and the polymer sheet facing down, spread the first web of the web according to the baseline, and then lay the second web. When laying the coiled material, the coiled material must not be forcibly stretched, and it should be aligned with the baseline at any time to avoid deviations that are difficult to correct.

●Long and short edge of the coil: the long edge of the coil is connected by self-adhesive bonding, the isolation film of the overlapped portion is removed, pasted on, and then rolled and exhausted; the short edge is used In the butt jointing method, stick the double-sided self-adhesive strip to the lower surface of the joint between the two webs, roll the exhaust or weld the polymer strip to the lower surface of the joint between the two webs.

●Organization acceptance.

Previous

Modified asphalt waterproof membrane for road bridge and high-speed railway

Online Consultation

More Products