Cement-based penetrating crystalline waterproof coating

Category:

Products

Summary:

● Cement-based permeable crystalline waterproof material is a gray powdery material formulated with ordinary Portland cement as the base material and mixed with active chemical components. Cement-based permeable crystalline waterproof material, its waterproof mechanism is mainly porous. Under the action of water, the waterproof material contains active chemical substances, using water as a carrier. As water penetrates into the pores of the structure, the active chemical substances The water penetrates into the interior and reacts to form insoluble crystals such as ettringite. The active chemical substance and the unhydrated cement particles undergo a hydration reaction, and promote the cement hydration, forming cement hydration crystals, generating a large number of crystal filling, sealing The pores are blocked so that water cannot enter the concrete, thereby achieving the purpose of waterproofing. <br/> ● Cement-based permeable crystalline waterproof material, due to its good adhesion, whether it is a light base surface and a wool base surface, a back water surface and a water facing surface, a dry base surface and a wet base surface, or a stagnant water base surface does not affect its construction effect .

Keywords:

Cement-based penetrating crystalline waterproof coating

Features

●This product is non-toxic and harmless, and is an environmentally friendly product;

●Has a long-term waterproof effect;

●With secondary impermeability and self-repair ability;

●It has the functions of anti-corrosion, anti-aging and protection of steel bars;.

●Simple construction.

Scope of application

Widely used in tunnels, dams, reservoirs, power stations, nuclear power plants, cooling towers, underground railways, overpasses, bridges, underground continuous walls, airport runways, pile head pile foundation wastewater treatment tanks, storage tanks, industrial and civil building basements, roof , Waterproof construction of toilets, and repair and plugging of all concrete structure defects such as concrete construction facilities.

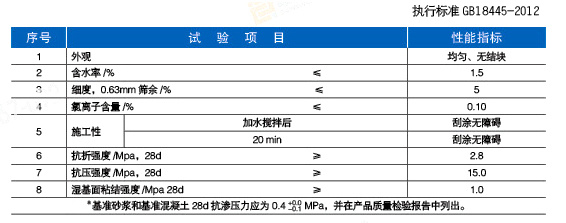

Main technical performance index

Precautions

●Construction at room temperature should not be carried out under the severe conditions of below zero degrees Celsius and rain, fog, wind and sand.

●Mixing water and curing water are best with drinking water, and unclean polluted water should not be used.

●Construction must be carried out on a concrete structure or a solid cement mortar base surface, not directly on the surface of the fly ash layer, the base surface should be clean and free of floating dust, old coatings, dust and other debris, to provide a fully open capillary system It is conducive to the penetration of this product and the formation of crystals.

●For all concrete to be painted with this product, you must carefully check whether there are structural defects, such as formwork rod holes, cracks, honeycomb pit-like inferior surfaces, pits, uneven unevenness at the interface of the construction joint, all should be Chiseling, cleaning, caulking, reinforcement, leveling, and then large-scale waterproof construction.

●For the construction of sanitary ware, special treatment shall be taken on the joint of the pipeline. You can cut a 10mm deep V-shaped groove along the junction of the pipe wall and the base surface to block it, and then make the base surface waterproof coating.

●Make sure the coating thickness and recommended dosage for construction. When applying the brushing method, if the slurry is too thin, the stirring is uneven, and the second addition of water, etc., it is easy to cause the base surface to powder or shine.

●If the concrete member needs to be backfilled with soil, the wet soil can be filled after 36 hours of construction, but the dry soil should not be backfilled within 7 days to prevent it from absorbing water into the waterproof coating.

Previous

Spray polyurea elastomer waterproof coating

Online Consultation

More Products