Polyvinyl chloride (PVC) waterproof membrane

Category:

Products

Summary:

● Homogeneous polyvinyl chloride (PVC) waterproof membrane is a kind of high-quality, high-molecular waterproof sheet, which is added with processing aids such as plasticizer, anti-ultraviolet agent, anti-aging agent, stabilizer, etc. through PVC resin. Method to produce molded polymer waterproof membrane. This product uses a unique product formula, the product life span far exceeds the general waterproof material, the entire waterproof system has a long life span, more than 20 years on the roof, more than 50 years on the ground, and is widely used in construction and civil engineering. <br/> ● Inner reinforced reinforced polyvinyl chloride (PVC) waterproof membrane is a kind of thermoplastic PVC membrane, which uses polyester fiber fabric or glass fiber as reinforcement, through a special extrusion coating process , The double-sided polyvinyl chloride plastic layer and the middle polyester or glass fiber ribs are combined into a polymer coil. The combination of advanced formula PVC target $ IA and mesh-structured polyester fiber fabric makes the coiled material have excellent dimensional stability and low coefficient of thermal expansion. The reinforcing ribs in the glass fiber are fully kneaded with the coil, so there will be no separation between layers and water immersion. Improve the long-term performance of the coil directly exposed to the natural environment. At the same time, the unique coating on the surface of the coil makes the coil self-cleaning, preventing the dust and pollutants in the air from coloring on the coil.

Keywords:

Polyvinyl chloride (PVC) waterproof membrane

Product advantages

●Mixing automation. The mixing of this project adopts automatic heating control, automatic time control, automatic eye material control;

●Extrusion equipment adopts twin-screw mutual aid, screw temperature adopts computer automatic temperature control system;

●The head adopts a large width die extrusion equipment with a width of 2.1m;

●Precise three-roll calendering device, the equipment spacing adopts automatic control and self-adjusting system.

Product Categories

According to the composition of the product:

H-Homogeneous membrane: PVC waterproof membrane without internal reinforcement or backing material

L-Fibre backing roll: PVC waterproof rolls laminated on the lower surface of the roll with fabrics such as polyester nonwovens

(The non-woven fabric composited on the back can play the role of leveling and height separation, and plays a key role in the adhesion of the adhesive. The coil is mainly used for full-adhesive roofing.

P-Reinforced coiled material in fabric: PVC waterproof membrane reinforced with polyester or fiberglass mesh in the middle of the coiled material

(The reinforcement in the poly-faced fabric of the coiled material can transfer the wind load on the tacking material to the screws fixed on the roof base.)

G.--. Glass fiber reinforced coil: adding chopped glass fiber or glass fiber non-woven fabric to the coil has no obvious effect on the tensile properties and other mechanical properties, but only improves the dimensional stability of the product. PVC waterproof Coil

(The glass fiber internal reinforcement of the coiled material makes the coiled material have excellent dimensional stability. The material is generally used for resurfacing roofing and detail treatment.)

GL-Glass fiber inner reinforced fiber backing roll: Add chopped glass fiber or glass fiber non-woven fabric to the roll material, and compound it with fabric such as polyester non-woven fabric, etc .:

PVC waterproof membrane on the lower surface of the membrane

(The glass fiber internal reinforcement of the coiled material makes the coiled material have excellent dimensional stability. The coiled material is suitable for pavement roofing and detail treatment.)

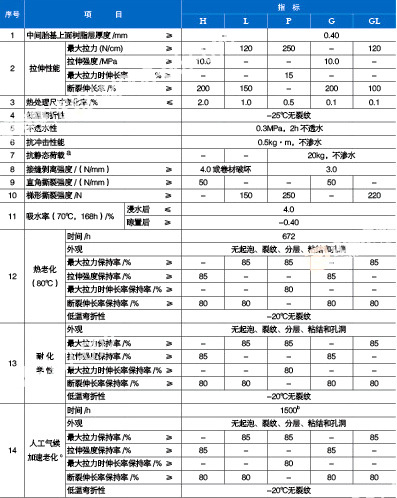

Product index

Features

●Long service life, aging resistance, roofing materials can be used for more than 20 years, underground for up to 50 years.

●High tensile strength, high elongation and small change in heat treatment size.

●Good flexibility at low temperature, good adaptability to environmental temperature difference.

●Good resistance to root penetration and can be used as a planting roof. .

●Good perforation resistance.

●Convenient construction, firm and reliable when welding, environmental protection and no pollution.

●Strong chemical resistance and suitable for special occasions.

●It has good plasticity, and it is convenient and fast to handle the corner details.

●Easy maintenance and low cost.

●With the function of self-sufficiency from fire.

Application field

Polyvinyl chloride (PVC) waterproof coiled material uses a unique product formula, which makes the product's life span far beyond the general waterproof material. The excellent performance of the coiled material is widely used in various fields of waterproofing.

Previous

Special waterproof coating for metal roof

Online Consultation

More Products